Background:

The National Park Service (NPS) stores, maintains, and displays historic collections, artifacts, and culturally significant pieces across various sites. Recognizing the need for efficient infrastructure, NPS seized the opportunity to relocate collections and archives from several sites in the Northwest Region into one larger facility at Fort Vancouver National Historic Site in Washington.

Key Objectives:

- Reduce deferred maintenance

- Decrease operation and maintenance (O&M) costs

- Address museum standard deficiencies

Site Selection:

NPS chose Fort Vancouver Building 405 as the repository for collections from four national parks, totaling over 3 million items.

Fort Vancouver Building 405 Rehabilitation Project

Facility Overview:

- An existing 14,000-square-foot 1980s aircraft maintenance hangar

- Selected for rehabilitation to serve as a museum collection storage facility

- Dedicated spaces for object and archival storage, curated labs, and public viewing areas

Public Engagement Spaces:

- Climate-controlled zones for high storage capacity

- Visible spaces for public viewing in a preservation-friendly manner

- Spaces for curatorial labs visible to the public

- Large gathering spaces for school field trips and general assembly use

Mechanical System Options by 360 Engineering

Discovery and Presentation on Anderson Hallas Architect’s Team:

- Based on our evaluation of the existing building and project goals, including 100% electrification, 360 Engineering explored various options

- Presented options in a “Choosing By Advantage” or Value Analysis format, providing three options

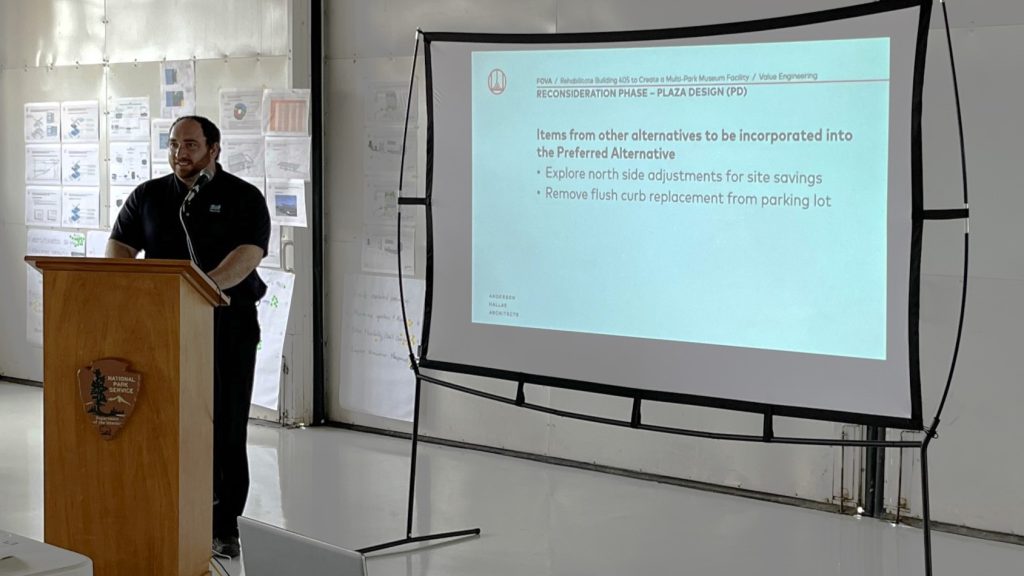

- Brennen Guy and Spencer Rioux presented to NPS staff at Fort Vancouver, addressing the pros and cons of each option

Variable Refrigerant Flow (VRF) System Selected:

- Reasons for Selection:

- Minimizes ductwork to maximize storage space

- Accommodates varying occupancies, including critical storage, laboratories, assembly spaces, library, and offices

- Aligns with NPS’ energy-efficient principles, promoting reduced consumption and fossil fuel reliance

Advantages of VRF System:

- Efficiently manages heating and cooling loads for diverse occupancies

- Facilitates refrigerant heat recovery between zones, reducing energy waste

- Aligns with NPS’ commitment to energy-efficient systems

Conclusion

Adopting the Variable Refrigerant Flow (VRF) system for Fort Vancouver marks a significant step in realizing NPS’ Service-Wide Curation Facility Plan. This decision ensures optimal preservation conditions for the extensive collection while promoting energy efficiency in line with NPS’ principles.