As summer comes into full swing and temperatures begin to climb, commercial and industrial facilities face increasing pressure to ensure their HVAC systems are operating at peak performance. One of the most critical components in large-scale cooling systems is the chiller. Whether you’re managing a hospital, data center, office complex, or manufacturing plant, upgrading your chiller system before the summer heat hits can make a significant difference in energy efficiency, occupant comfort, and operational reliability.

Here’s what you need to know before investing in a chiller system upgrade.

1. Assess Current System Performance

Before considering an upgrade, conduct a thorough performance assessment of your existing chiller system. Look for signs of inefficiency such as:

-

- Rising energy bills

-

- Inconsistent cooling

-

- Frequent maintenance issues

-

- Equipment nearing or past its expected service life

Modern chillers are significantly more efficient than those installed even a decade ago. If your system is more than 15 years old, an upgrade could reduce energy consumption significantly.

2. Understand Your Cooling Load Requirements

Chiller systems should be sized based on actual cooling load demands, not outdated or estimated figures. Consider the actual occupancy and usage of your building, as well as any other facility upgrades that may have been implemented previously (such as window replacement, improved insulation, even office equipment moderniziations). Over- or under-sizing can lead to inefficiencies, increased wear and tear, and higher operational costs. A professional load analysis will help determine the optimal capacity and configuration for your facility’s current and future needs.

3. Explore Energy-Efficient Technologies

Today’s chiller systems come equipped with advanced technologies that offer superior performance and energy savings:

-

- Variable Speed Drives (VSDs): Adjust compressor speed based on load, reducing energy use during partial load conditions.

-

- Magnetic Bearing Compressors: Eliminate oil and reduce mechanical friction, improving efficiency and reliability. These systems typically allow for significantly greater turndown at part-load conditions as well—that is, the chiller can operate efficiently at reduced capacity, conditions at which other types of chillers would need to shut down entirely to protect their internal refrigeration components!

-

- Free Cooling Options: Use ambient air or water when conditions allow, bypassing the compressors (i.e. the primary energy users in the cooling system) entirely to save energy.

Incorporating these technologies can also help your facility qualify for utility rebates and sustainability certifications like LEED O+M.

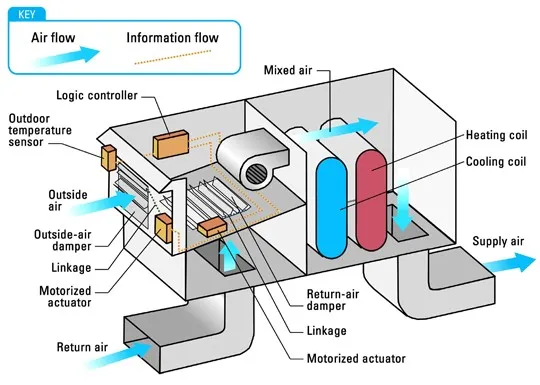

4. Consider System Integration and Controls

Upgrading your chiller is only part of the equation. Integrating it with a modern Building Automation System (BAS) allows for real-time monitoring, predictive maintenance, and optimized performance. Smart controls can adjust chiller operation based on occupancy, weather forecasts, and energy pricing, further enhancing efficiency.

5. Plan for Downtime and Installation

Chiller upgrades can be complex and may require temporary system shutdowns. Planning ahead is crucial to minimize disruption. 360 can help building owners navigate these challenges, working with vendors, contractors, and facility staff to:

-

- Schedule installation during off-peak hours or cooler months

-

- Coordinate with other building systems

-

- Ensure proper commissioning and testing

A well-executed upgrade plan ensures a smooth transition and long-term performance benefits.

6. Evaluate Lifecycle Costs, Not Just Initial Price

While upfront costs are important, the total cost of ownership—including energy use, maintenance, and lifespan—should guide your decision. A slightly more expensive chiller with higher efficiency and lower maintenance needs can pay for itself in just a few years.

7. Partner with the Right Engineering Firm

Choosing the right HVAC design engineering partner is key to a successful chiller upgrade. 360 Engineering is a firm with:

-

- Proven experience in chiller system design and retrofits

-

- Knowledge of local codes and energy standards

-

- A track record of delivering energy-efficient, cost-effective solutions

Final Thoughts

Upgrading your chiller system before the summer heat arrives isn’t just a smart move—it’s a strategic investment in your facility’s performance, sustainability, and bottom line. With the right planning and expertise, you can ensure your building stays cool, efficient, and resilient all season long.

Need help evaluating your chiller system? Contact our team of HVAC design experts today to schedule a consultation.

Contact Us