Last month, we summarized some of the why and how of electrification related to mechanical and plumbing systems. When it comes to all-electric HVAC, the common denominator is refrigerant. Just about any mechanical system providing heating and/or cooling without using fossil fuels will include refrigerant at some level—heat pumps, chillers, geothermal they all include refrigerant compressor circuits. So, on top of local, state, and federal regulations pushing the industry toward building systems electrification, Congress has kept things interesting by passing the AIM Act in 2020.

The AIM Act and Refrigerant Regulation

The American Innovation and Manufacturing (AIM) Act grants the Environmental Protection Agency (EPA) the authority to regulate and phase out hydrofluorocarbon (HFC) refrigerants in the coming years. HFCs are potent greenhouse gases with a global warming potential (GWP) thousands of times higher than carbon dioxide (GWP = 1). To combat this, the EPA has set GWP limits for refrigerants manufactured or imported in the U.S.

Impact on the HVAC Industry

Current Refrigerant Landscape: Most heat pumps (including water-source heat pumps, variable refrigerant flow systems, etc.) and DX cooling units currently use R-410a refrigerant, boasting a GWP rating of around 3,000.

EPA’s GWP Limits: Starting in 2025-2026, the EPA mandates a GWP limit of 700 for refrigerants in these systems. Other types of equipment (such as supermarket refrigerated displays) have even lower GWP limits.

Industry Response: HVAC equipment manufacturers are investing significant time and effort in redesigning equipment to accommodate alternative refrigerants that comply with EPA requirements.

Choosing the Right Refrigerant

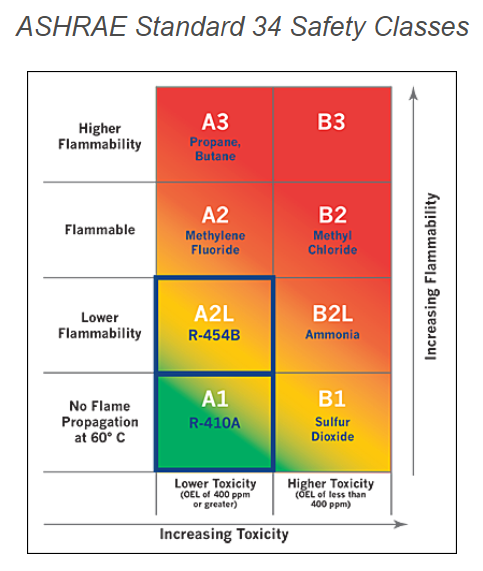

- Various refrigerant options are available, but only a few are practical replacements for HFCs in HVAC systems.

- Selection involves economic considerations and evaluation of potential life-safety risks.

- Codes and standards such as the International Mechanical Code and ASHRAE Standard 15 guide allowable refrigerant volumes based on health hazards, flammability, and reactivity.

- Our job as engineers is to calculate and confirm that a leak in the piping or equipment we’ve specified would not result in a concentration above this limit inside the smallest enclosed space served by our system.

Understanding Allowable Concentrations

- For instance, R-410a has an allowable concentration of 26 lbs. per 1,000 cubic feet, with a health hazard rating of 2 (coupled with flammability and reactivity hazard ratings of 0).

- R-32, a potential R-410a replacement, has a lower health hazard rating of 1 but a higher flammability hazard rating of 4, resulting in an allowable concentration of only 4.8 lbs. per 1,000 cubic feet.

Implications for HVAC Systems

- The AIM Act’s impact extends to architectural, electrical, and structural designs.

- Uncertainty remains about manufacturers’ refrigerant choices and their effects on system designs.

- Potential changes could lead to larger equipment and piping, challenging installation, maintenance, and clearances.

- Increased electrical loads may strain infrastructure, especially in buildings aiming for full electrification.

In summary, while the HVAC industry faces uncertainty due to the AIM Act, it is actively preparing for the changes. As engineers, we anticipate and embrace these challenges and are excited about the innovations driving our industry toward a more efficient and sustainable future.

For further details, visit the International Code Council website.