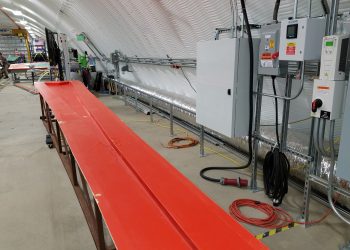

Located at NREL’s Flatirons Campus, the Composites Manufacturing Education and Technology (CoMET) facility enables NREL to lead composite research projects for the wind turbine industry. As part of 360 Engineering’s IDIQ contract with NREL, the firm was selected to provide a new R-19 insulation system to this existing pre-engineered metal building. 360 Engineering led the design team, including Anderson Hallas Architects, Martin/Martin for structural engineering, and AE Design for electrical engineering.

The architect used WUFI modeling to determine the location of the vapor barrier and the system’s feasibility. Martin/Martin evaluated the existing structure to verify its capability of supporting the additional insulation and offered a design for minor support of a new architectural roof system. 360 Engineering determined the dew point, proposed systems to mitigate interior condensation, and designed a retrofit to add a DX coil to the existing 100% outdoor air unit, as well as provided new controls for the existing unit to tie into the campus BAS. Additionally, 360 calculated the new space heating load and designed new gas unit heater installations to cover and reduce the load on the existing electric coil in the 100% outdoor air unit. AE Design designed the removal and reinstallation of exterior lighting and power to new unit heaters and DX unit.

Based on the design team’s analysis and reporting, it was determined that Roofing Option 1 (spray foam insulation) was the only feasible choice due to the maximum allowable structural load parameters. 360 Engineering led the team through design and into construction administration, completing a final punch report once construction was finished.