At 360, we love to be team players and share our ideas and insights with our fellow consultants. And boy, do we have ideas! This month, we wanted to help out our architect friends with some brilliant tips and tricks for working with mechanical engineers and making buildings awesome.

Chase Sizes

Everyone loved throwing things down the laundry chute as a kid, so why not bring that excitement to the workplace by adding chases sprinkled throughout the floorplan? Never concede to smaller chases, as they should occupy no less than 25% of the floor. Oh, and make sure you can fit some ductwork and pipes in there if possible. (Picture shown for reference of a building chase)

Do: Provide chases with a minimum of 100 square feet, a large access panel (preferably 3’ wide and 7’ tall with a handle or knob for entry), and a large glass panel to allow observations from outside.

Don’t: Provide only one chase in the building. It may feel entitled and eventually resent the occupants.

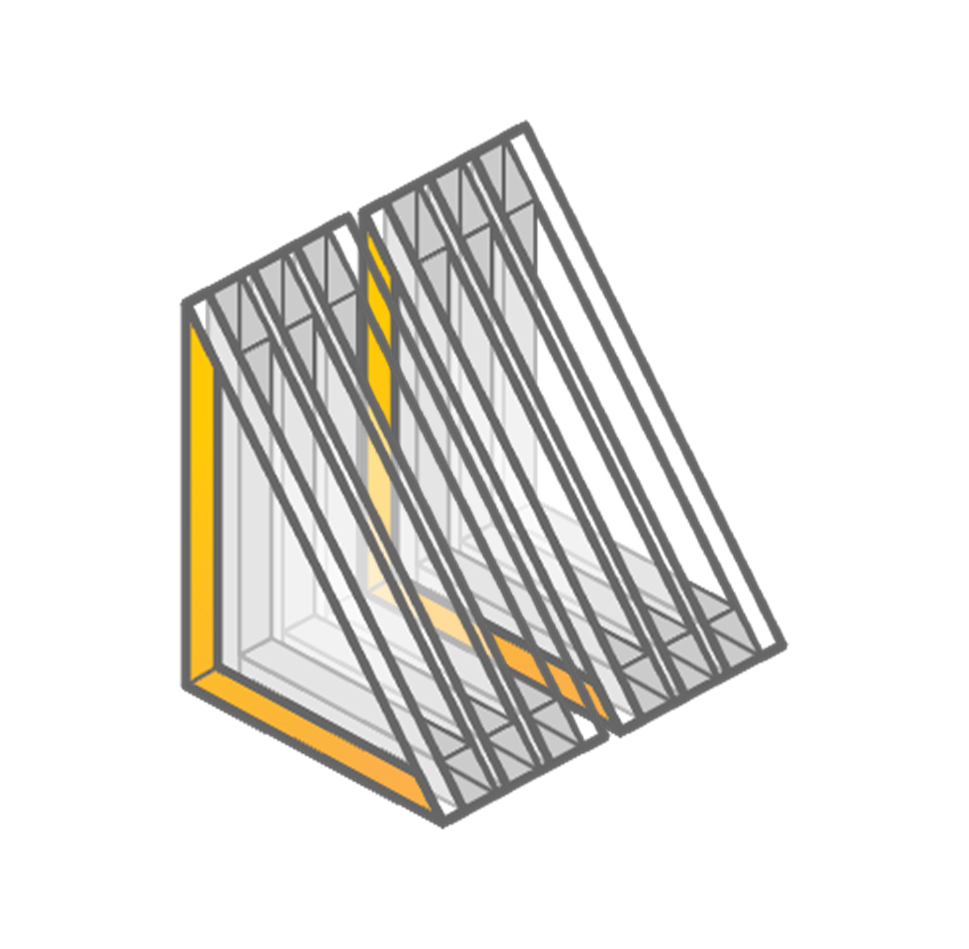

Quadruple Paned Windows

Everyone wants to fight for the window seat in the office, but no one wants the perks of afternoon glares, cold spots, and the potential of pedestrians looking in. There are many architectural advances to mitigate those risks, but none more effective than quadruple-paned windows. The more layers you add, the less heat transfers through the window, and the harder someone will have to squint to see inside. While quadruple-paned windows may be a good option, why stop there? Double stacking quadruple pane windows is an even more effective way to not only introduce unique light reflections in the space but also add architectural personality to buildings with windows that are thicker than the walls.

Do: Install double-stacked (heck, even triple-stacked) quadruple-pane windows.

Don’t: Default to the cost-effective, low solar gain, and easy-to-install windows.

Insulation Thickness

Insulation is best described as the warm blanket in the walls that the framing snuggles to keep warm at night. Traditionally, insulation is installed using rigid boards, spray foam, or stuffed batt insulation. However, to give a modern approach to building insulation, we recommend installing rigid dish sponges, silly string spray, or stuffed goose feather pillows as a much better insulation material. If you don’t have any of those materials handy, just stuff the walls with whatever you can find. It’ll be fine!

Do: Provide a wall stuffed full of Kleenex to reduce the HVAC size needed and use the previous batt insulation as blankets on the couch—just be prepared to be extremely itchy as you binge the newest season of Real Housewives.

Don’t: Provide boring rigid or batt insulation in the walls.

Disclaimer: This blog post was released on April 1st, and while 360 Engineering is not a licensed architecture firm, we do have some really great ideas for the advancement of architecture! Call us about your next project; we’ve got quadruple-paned windows ready for you!